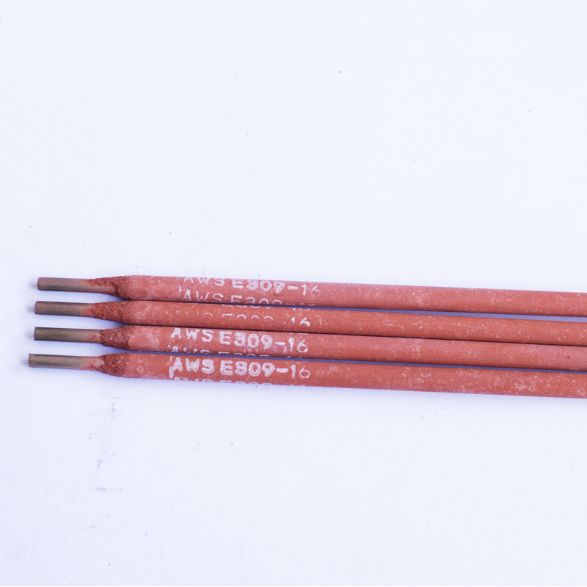

2.5mm small splash carbon steel welding electrodes aws e6013

Carbon steel electrode (the tensile strength of deposited metal is less than 500MPa or 50kgf/mm2) is suitable for welding carbon steel and low strength low alloy steel. For low hydrogen type and iron powder type electrode, the electrode must go through 350 ° C or above baking before welding, otherwise, there will be welding defects (such as porosity, slag inclusion, cracks, process performance deterioration, etc.) . The cellulose type electrode should be baked according to the baking temperature specified in the specification. If the baking temperature is too high, the cellulose in the coating will be burned off and the inherent technological properties of the electrode will be destroyed. When using the low hydrogen type electrode, the welder should live in the upwind position, strengthen the ventilation, prevent the harm of welding fumes to the body. The baking times of the low hydrogen type electrode should not exceed two times as far as possible to prevent the coating from becoming brittle and falling off.

| Model | GB | AWS | Diameter(mm) | Type of Coating | Current | Uses |

| CB-A132 | E347-16 | E347-16 | 2.5-5.0 | Lime-titania Type | AC,DC | Used for welding key corrosion resistant 0Cr19Ni11Ti stainless steel containing Tistabilizer. |

Chemical Composition of Deposited Metal

| Chemical Composition of Deposited Metal (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

Mechanical Properties of Deposited Metal

| Mechanical Properties of Deposited Metal | |

| Rm(Mpa) | A(%) |

| ≥520 | ≥25 |

Packing

Our Factory

Exhibition

Our Certification